Products Selector > Related Products

Heat Reflective Sleeve - Aluminum Foil and Aluminized PET Film Coated Fiberglass

Radiant Heat Reflective Protection for Wire, Cables, Hoses and Tubing

These high temperature, heat resistant and radiant heat reflective sleeves can be used to protect industrial wires, cables, hoses (hydraulics), piping and tubing from radiant heat sources such as glowing steel slab, liquid metal pour stream, engine headers, infrared heaters and other similar heat sources. These sleeves are used extensively for automotive and truck under-hood engine compartment applications.

These sleeves slides easily over wires, cables and hoses due to the smooth inner fiberglass surface. This aluminized sleeve reflects more than 95% of the radiant energy that hits its surface, keeping the underlying cables, hoses and wires cool.

Generally, aluminum foil coated fiberglass is suitable for applications involving static hoses, cables and wires. For installation where continuous movement or flexing is involved, the aluminized PET film coated fiberglass is more suitable. Also available is a solid wall annular corrugated stainless steel sleeve.

450°F / 232°C Continuous Exposure / 1000°F / 537°C Peak Exposure

Aluminized PET Film Coated Fiberglass Heat Reflective Continuous Sleeve

Available in 100 and 250 foot spools - also available in cut by-the-foot lengths

Available in sizes from 1/2" through 2.5" ID.

Aluminized PET coated fiberglass is suitable for applications where flexing is anticipated and may be more suitable to aluminum foil coated sleeves as the aluminum foil in flexing applications can crack and peel.

Aluminized PET Film Coated Fiberglass Heat Reflective Sleeve - High Bulk Convoluted

Available in 4 foot / 121.9cm long sticks.

Available in sizes from 1/2" through 2.5" ID.

This heat reflecting sleeve is a high-bulk and convoluted construction. The fiberglass substrate has a PET inserted filament included with the fiberglass fibers, providing good crush resistance and pushback against compression.

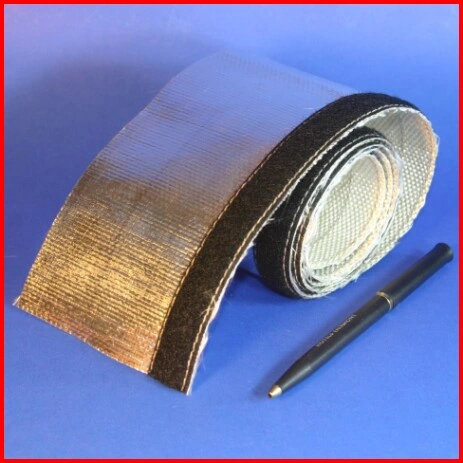

Aluminized PET Film Coated Fiberglass Heat Reflective Split Sleeve with adhesive closure strip

Available in 4 foot / 121.9 cm length sticks.

This aluminized PET film coated fiberglass split sleeve has an adhesive strip along one long edge to close the sleeve after installation.

Available in sizes from 1/4" through 2" ID.

This sleeve is also used extensively for automotive, construction, mining and truck under-hood engine compartment applications. The fiberglass substrate also has a PET inserted filament included with the fiberglass fibers, resulting in a sleeve that resists crushing and actively pushes back against compression.

Aluminum Foil or Aluminized PET Film Coated Fiberglass Heat Reflective Sewn Sleeve / Sleeve with Hook and Loop Closure

Available in two versions:

- Aluminum Foil coated fiberglass base material

- Aluminized PET Film coated fiberglass base material.

Aluminum Foil version is suitable for static applications with little to none movement after installation.

- For the aluminum foil version - a layer of highly polished aluminum foil is calendared under high pressure and with an adhesive onto a high temperature fiberglass base fabric. That fabric is slit into an tape, which is then sewn into a sleeve.

Aluminized PET Film version is suitable for repetitive flexing, movement or high vibration installations.

- For the aluminum film version - an aluminized PET film is laminated onto a high temperature fiberglass base fabric - which is then slit into a tape - and then sewn into a sleeve.

Other versions of the same materials are available with hook and loop closure or zipper closure; resulting in a removable or retrofit sleeve.

Available in sizes from 1/2" through 12" ID. Larger sizes are available under special order. Two weights of the aluminum foil fabric are used to make these sleeves: a 21oz/square yard and a 35oz/square yard. The 21oz material has better aluminum adhesion for applications requiring some flexing. For the aluminized PET version, the fabric weight is 20oz/square yard.

A four layer aluminum foil coated fabric is available. This fabric is more robust, but quite stiffer than a single layer aluminum coated fabric.

The reduced continuous temperature limit of this material is due to the adhesive used to help bond the aluminum foil layer to the fabric. Notwithstanding the temperature limit, intense radiant heat can be reflected while still under the continuous temperature limit.

Sewn sleeve:

Sleeve with Hook / Loop Closure:

Aluminized PET Film Coated Fiberglass Heat Reflective Sleeve with Zipper Closure

The base fabric is slit into a tape, which then has a zipper closure added to result in a sleeve that can be installed and removed at will.

Available in sizes from 1" through 12" ID. Larger sizes are available under special order. Fabric weight used to make these sleeves is 21oz/sq.yd. Other fabric weights may be available upon request.

The material is suitable for use in high flex and movement applications.

The reduced continuous temperature limit of this material is due to the adhesive used to help bond the aluminum film layer to the fabric. Notwithstanding the temperature limit, intense radiant heat can be reflected while still under the continuous temperature limit.